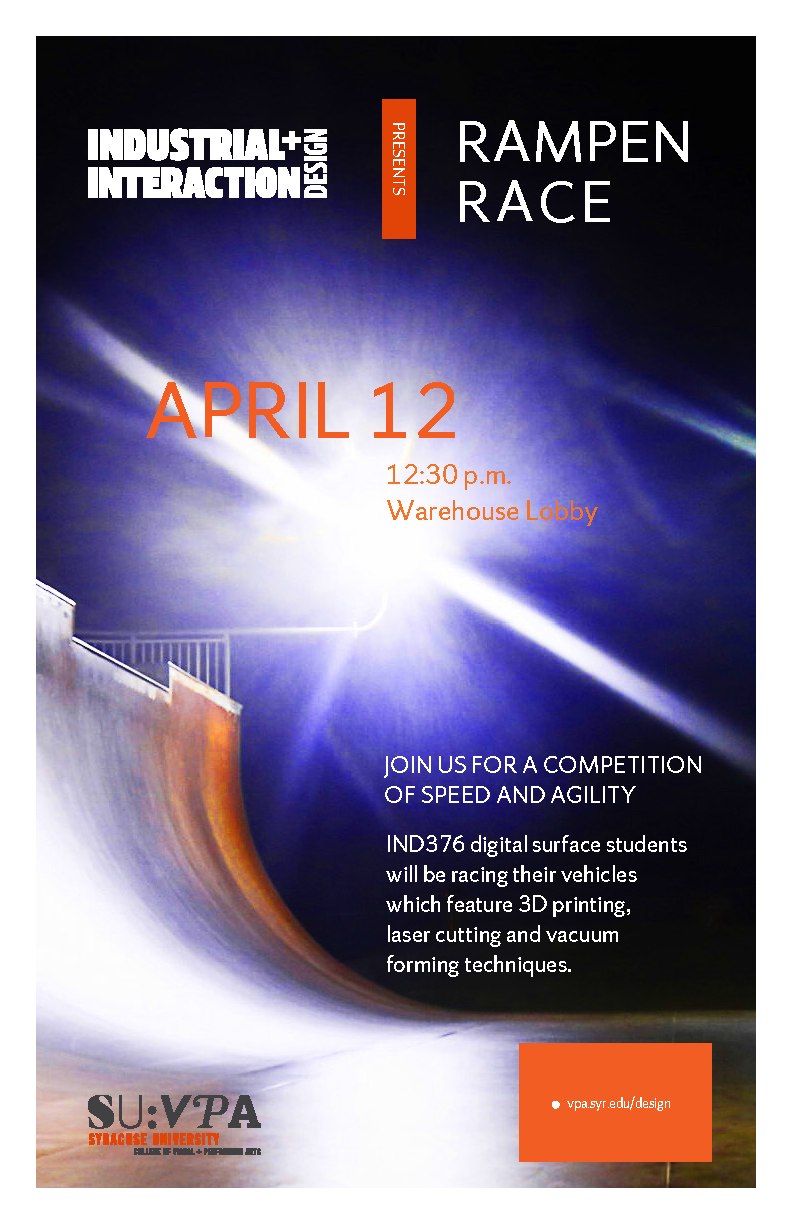

Digital Surface | Ramp Race

The Ramp Race is a project that emphasizes teamwork, besides providing ample opportunities to introduce critical CAD skills. Students work in teams of two and compete on race day with their peers. The Ramp Race event happens during lunch time in the warehouse lobby, adding visibility of our program in school of design and the community.

The teams receive a package of finished and semi-finished goods (608 wheel bearing, o-ring, acrylic sheet, screws). They have to adhere to specific constraints and use rapid prototyping tools (3D printer, laser cutter and vacuum former; min. 1 part each tool).

| Wheelbase | 7” +/- 0.25” |

| Front track/rear track | 5” +/- 0.25” |

| Wheel diameter | Rim: 50mm, must fit o-ring -size 1-3/8” ID, 1-3/4” OD, 3/16” Width); 4x provided |

| Wheel bearing | 608, 8x22x7mm; 4x provided |

| Weight | 550g +/-10g |

| Max. Size | fits within: 8” L x 6” W x 5” H |

| Rapid prototyping methods | Laser Cutting (chassis); Acrylic Sheet 2x provided, 3D Printing (axels, wheels, etc), Vacuum Forming (body parts/outer shell) |

While developing their vehicle that is powered only by kinetic energy when it is released from the top of the ramp, each team has to simultaneously work on the digital twin and the actual parts, making sure the provided parts fit with their own. The ramp is accessible for ongoing testing and the event is advertised in VPA.

On race day, the vehicles are lined up for inspection.

The rules for the competition are explained and the race takes its course. The distance travelled is the deciding metric for success. Each team sets up their run.