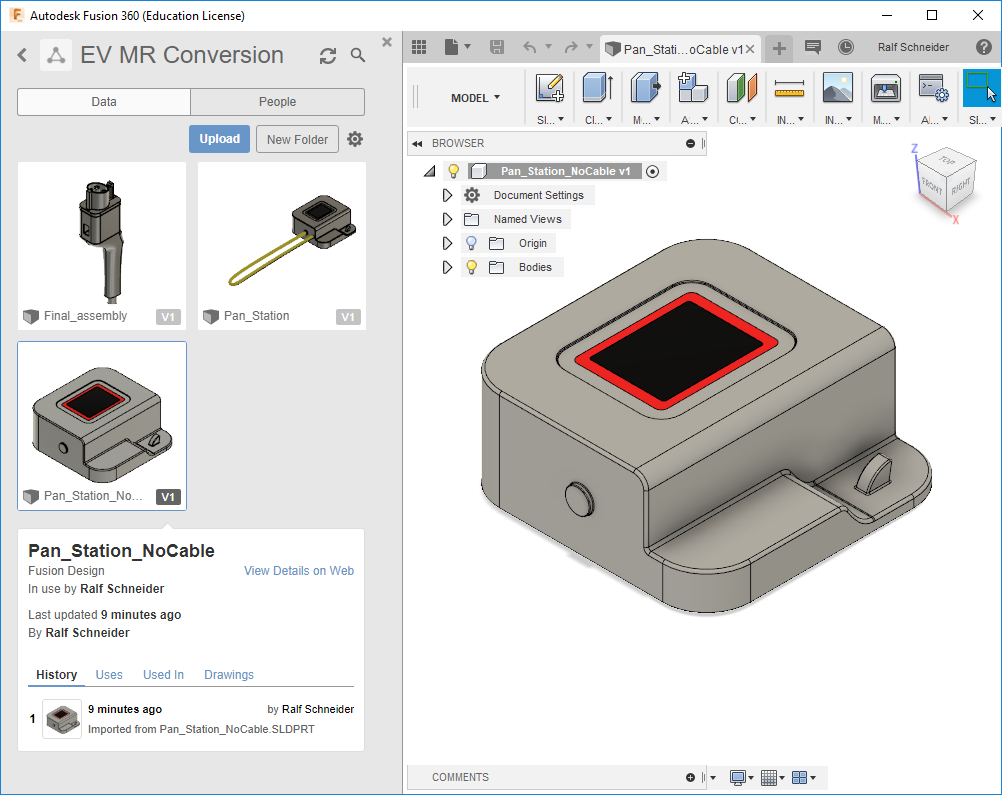

This week I worked through another workflow issue: How to export a SolidWorks file as an FBX, so it can be utilized in Unity. The SolidWorks file is easy to open in Fusion360. So far so good.

If you look for an “export as fbx” option, you won’t find it here. Instead you need to click the v1 field in the lower right to open the detailed file information window. Then click on “view details on web”.

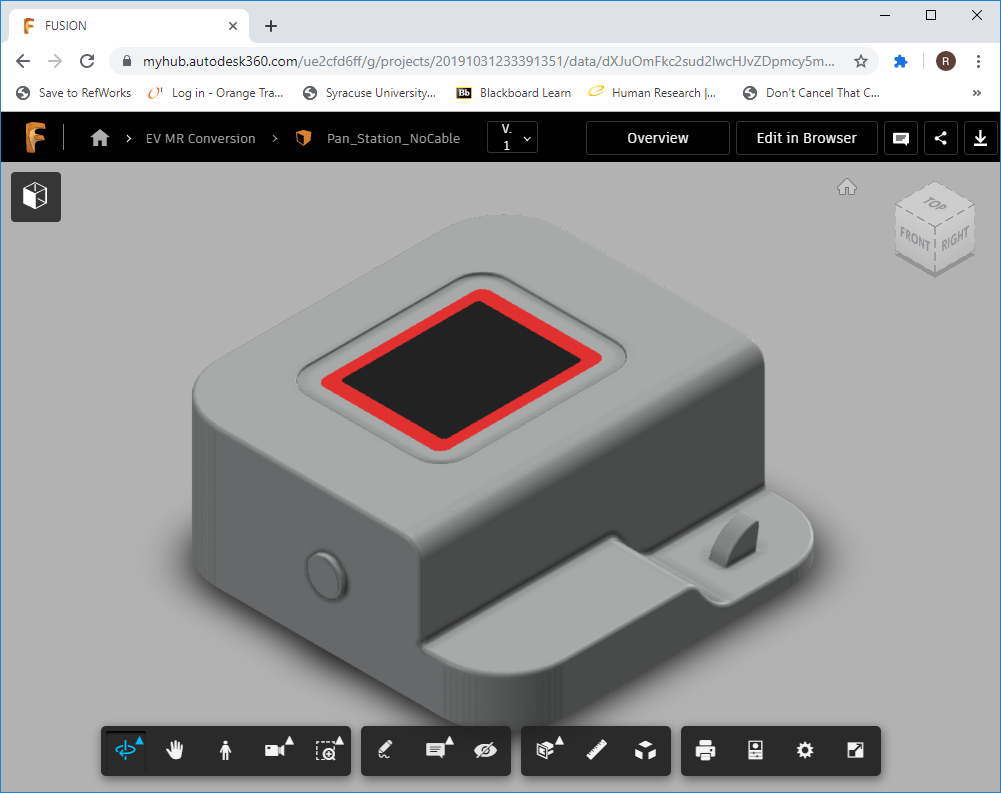

The default browser window opens and loads the Fusion360 web application.

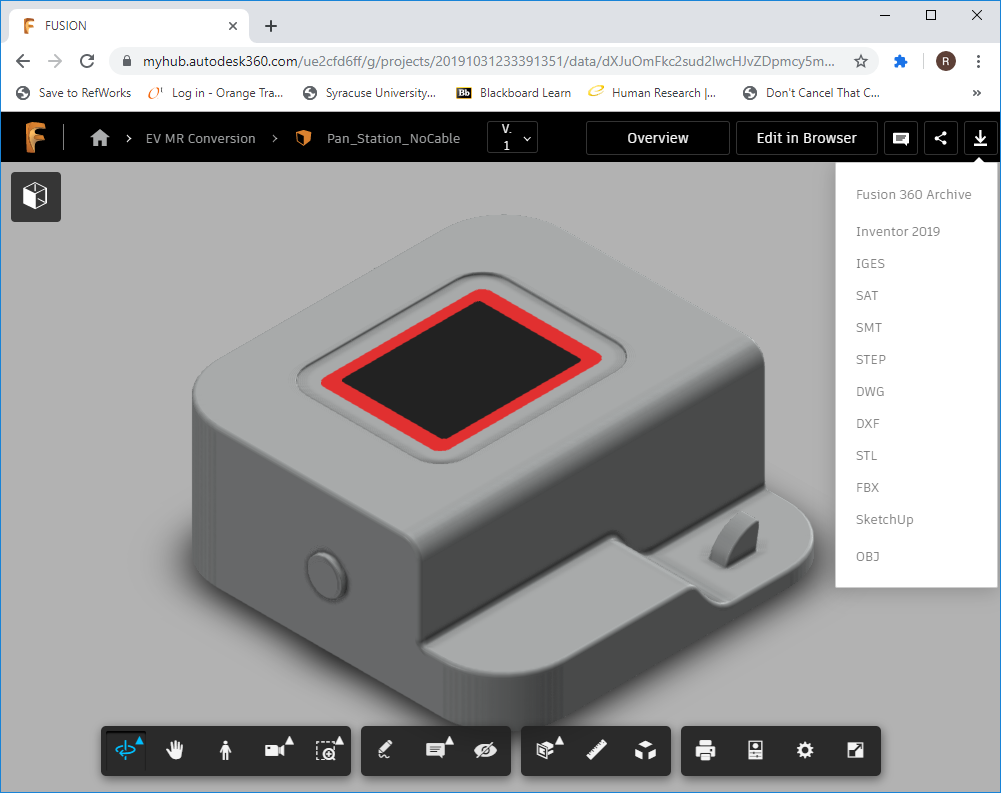

The icon with the arrow pointing down to the far right allows the export as FBX option.

After you click that you have to wait for an email with the link to an automatic file download.

After FOUR CLICKS you have exported the file, which imports into unity with a default mesh and default shader.

Blog

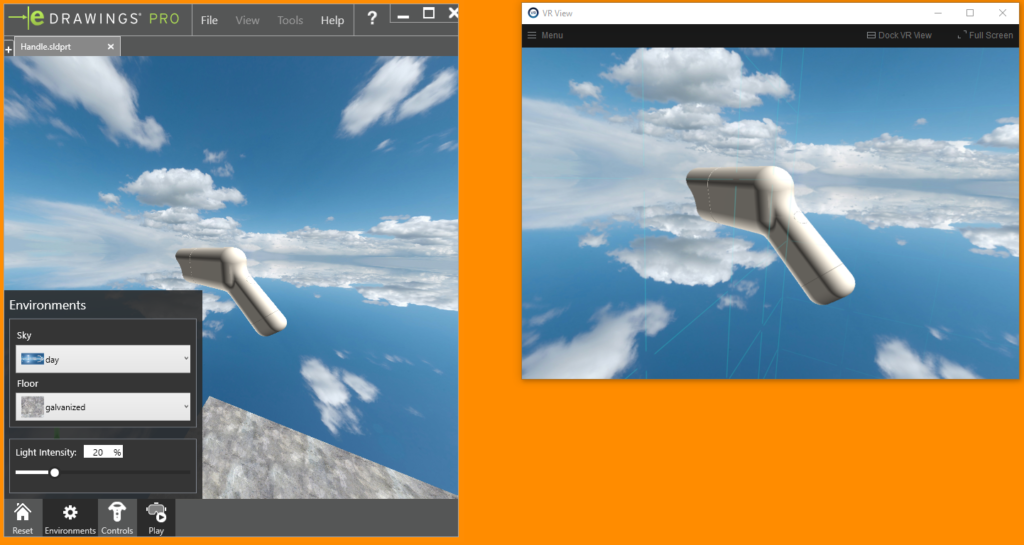

Testing SolidWorks eDrawing VR (in Beta)

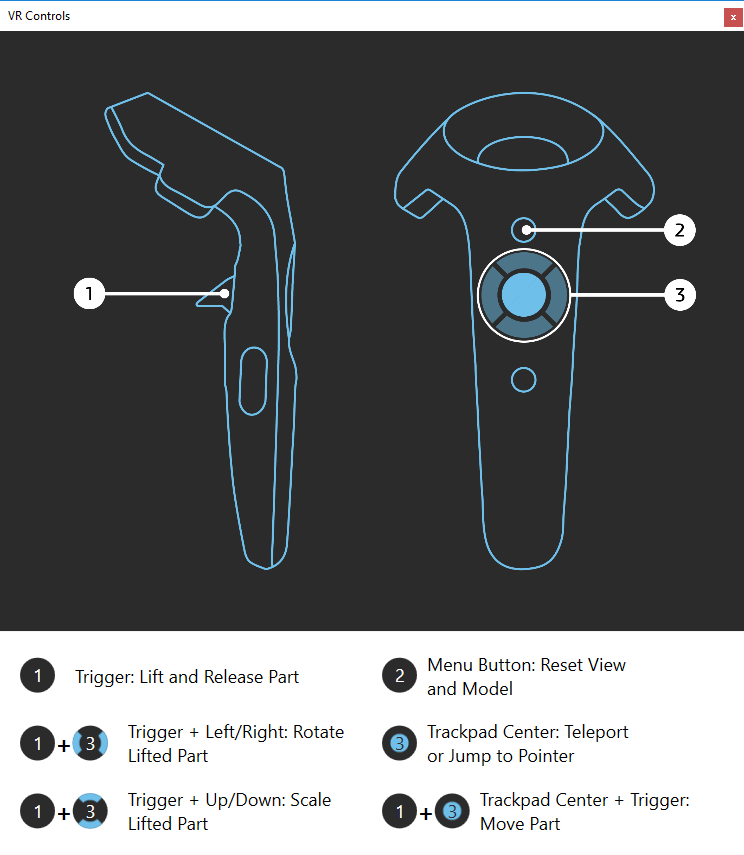

SolidWorks (SW) eDrawing allows the user to open a SW file and view the model in VR. In comparison to the Steam VR Viewer, it is important to resize the window for the on screen VR display to void a stretched or compressed image.

The VR Controller enables picking , holding and releasing a part in space.

Teleporting is helpful for larger scale objects. By default the part is positioned on the floor, which is based on the Steam VR setup calibration. That is a bit inconvenient when you need to pick up smaller handheld items. It would be helpful to have a feature for customizing the default setting for the object anchor.

Teleporting is helpful for larger scale objects. By default the part is positioned on the floor, which is based on the Steam VR setup calibration. That is a bit inconvenient when you need to pick up smaller handheld items. It would be helpful to have a feature for customizing the default setting for the object anchor.

While holding the part, the user can rotate and scale the object. Although the interaction is very limited and the experience at this point lacks customization, it is a super fast approach to review a digital twin in VR.

However, handling assemblies with multiple parts increases the challenges. In this case, the object is scaled down and is positioned too low. When moving parts of an assembly, the part is auto rotated in relation to the controller, which forces the user to make awkward moves. Furthermore, when doing so, the parts are scaled to different sizes. argh…

Raymond VR Donation

Thank you, Raymond Corporation, for donating 3 oculus rift to our program. Since HTC Vive was a better fit for the enterprise needs of the Raymond VR training, we are lucky to receive these brand new VR sets.

Students can check them out in our Digi Fab Lab.

3D printed replacement parts

Chrome plated plastic parts attract the consumers eye, but as we can see in this example do not age well. On the left is the Group Cowling of my espresso machine Rancilio Silvia. Not exactly a sustainable element of the machine, I decided to reverse engineer and 3D print the replacement part (on the right).

So far, the part has lasted almost three years. This experiment leads me to the following hypothesis: Someday, many people will be able to make their own replacement parts at home and in addition customize the result. (TBC…)

Invited to Raymond VR AR Symposium

I was invited to speak at the VR AR Symposium hosted by Raymond at their headquarters in Greene, NY. Among an international group of attendees, I shared outcomes of my Mixed Reality Research with industry on August 20 2019.

I was invited to speak at the VR AR Symposium hosted by Raymond at their headquarters in Greene, NY. Among an international group of attendees, I shared outcomes of my Mixed Reality Research with industry on August 20 2019.

Autonomous Systems Symposium

Attending the Symposium on “Autonomous systems and their policy, law, and governance” organized by Autonomous Systems Policy Institute / Maxwell School of Citizenship and Public Affairs at Syracuse University

This topic is one of the great use cases for Mixed Reality applications.

35th NCBDS conference

Today I am presenting my talk “Mixed Reality Redefines Spatial Visualization Opportunities” at the 35th National Conference on the Beginning Design Student (NCBDS) at the University of Colorado Denver.

I was able to fly into Denver Wednesday morning as the “bomb cyclone ” hit the region with 50 mph winds. The A-train took 2h to push through the blizzard like conditions (usually a 40min ride). Businesses closed at 2pm.

Podcast: Versatilist with Ralf Schneider

Based on a conference presentation at the NCBDS 34, my paper attracted the attention of Patrick O’Shea, the creator of the podcast “The Versatilist”.

He contacted me last fall and asked if I would be willing to talk about my research. The podcast episode was recorded in December 2018 during a skype video conference and is available here:

interaction19

Looking forward to presenting our talk Designing Inside the Model with my colleague Prof. Dianna Miller at the IXDA conference interaction19 in Seattle. The theme of the conference is “Design in the Wild”.

We will be sharing our most recent research work.

Frameless Symposium @RIT

Excited to be a speaker at the frameless symposium today. I will be showing various approaches to mixed reality ideation.