The Concept: Modular Precision

The Challenge

Contemporary living spaces are increasingly fluid. Homes become offices, dining rooms transform into workshops, therefore furniture must adapt. It is often difficult to find the right size for the intended spot.

The Solution

GRIDWERK is a modular furniture system that puts customization in users’ hands. Built on standardized aluminum profiles and precision-milled wood panels, it enables infinite configurations from a single, elegant design language. Users can prototype their ideal piece digitally, then bring it to life through on demand manufacturing. The order is Flat-Pack Efficient and ships disassembled, which reduces transportation emissions.

Design Vision

GRIDWERK celebrates honest materials and tough construction. The 2020 aluminum profile, an industrial standard, becomes a design statement. In combination with walnut veneer plywood, which adds warmth, the cool silver metal and the wood stand in contrast and heighten each other.

The modular advantages allow furniture as adaptable infrastructure for living instead of furniture as disposable commodity. Individual components can be swapped without replacing entire piece. Aluminum and wood separate cleanly for recycling, which optimizes End-of-Life Recovery.

System Architecture

Structural Frame

2020 Aluminum Profile

Industry-standard T-slot extrusion

20mm × 20mm cross-section

High strength-to-weight ratio

Integral T-slot grooves for panels

No welding required

Corner Cubes connected with

stainless steel Torx screws

Infinitely recyclable

Surface Panels

CNC-Milled Walnut Veneer Plywood

Precision-milled edges fit T-slots

Varnished finish for durability

Maximum wood utilization

Natural material warmth

Sustainable forestry sources

Replaceable if damaged

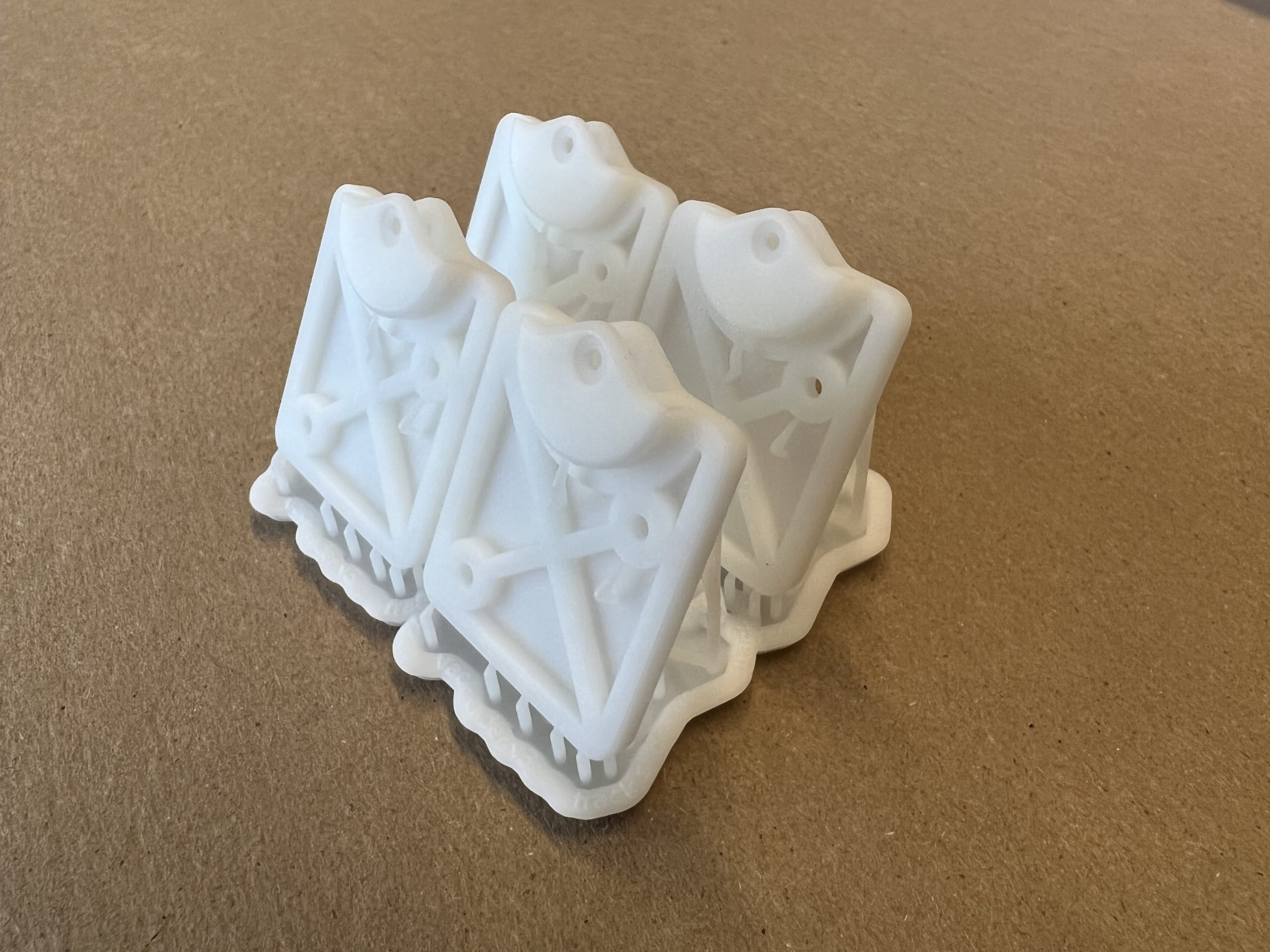

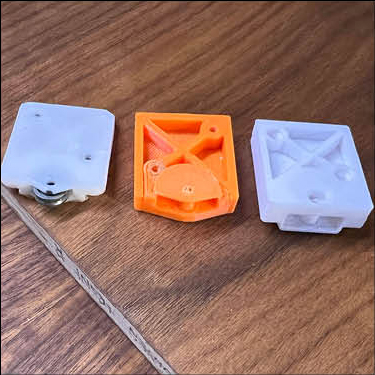

3D Printed Hardware

The sliding doors glide on ball-bearings that are mounted inside the 3D printed bracket, which fits flush in the wood panel.

Since the cut out is on the backside of the sliding door, this detail is invisible from the front.

Multiple iterations were needed to achieve a functional ball-bearing mount inside a 1/2 inch thick door.

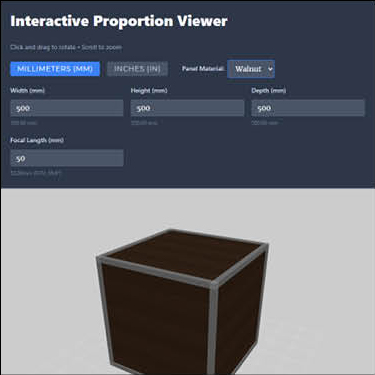

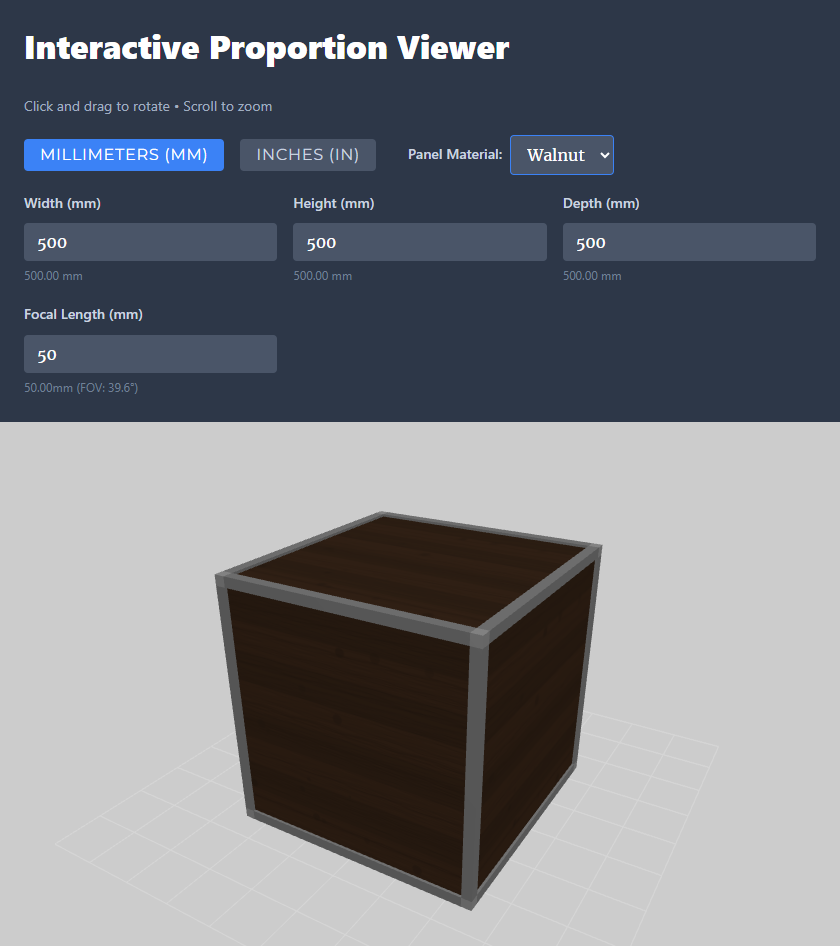

Interactive Proportion Viewer

I created the three js website code to support the user in experiencing the main advantage of this concept: Infinite Configurations

This interactive proportion viewer allows the user to configure the desired proportion. The 3D visualization helps understanding the differences in changing the x y and z values of a cuboid volume.

Prototype 1: Mobile Storage Cube

Prototype 2: Sideboard with Sliding Doors

Prototype 3: Wall-mounted Shelf

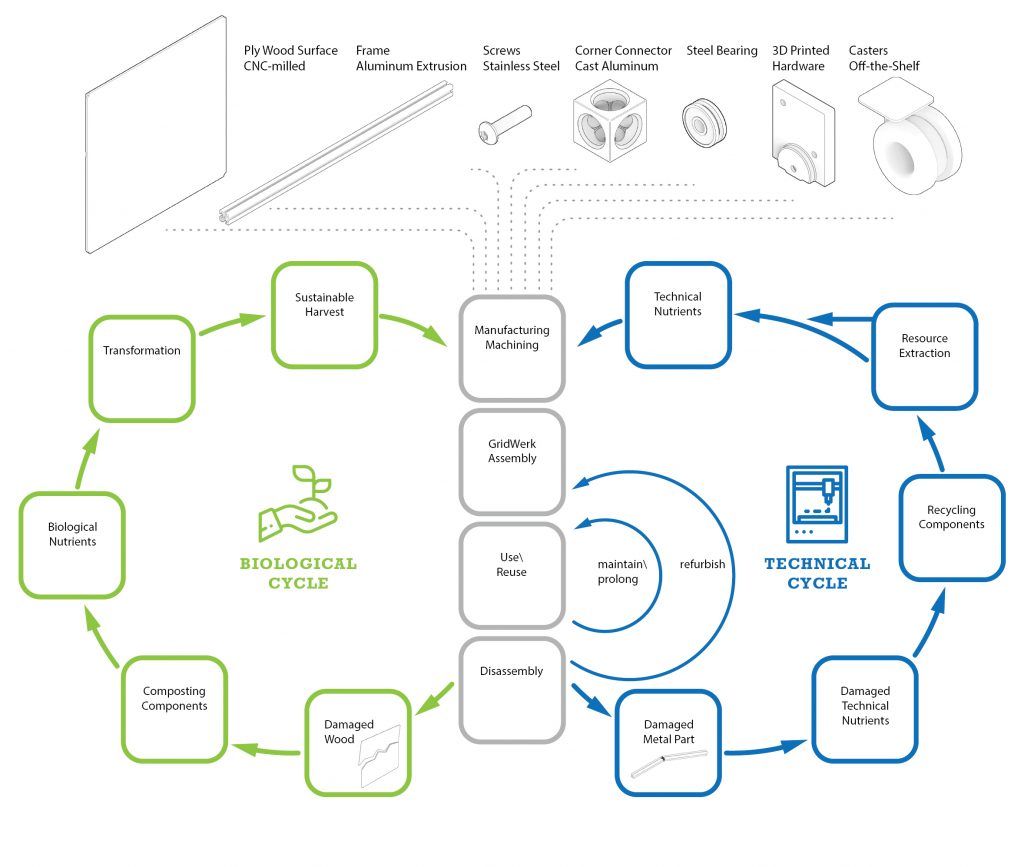

GRIDWERK and Sustainability

GRIDWERK addresses sustainability through material choice, longevity, and circular design principles

Technical Cycle: Aluminum

Infinitely recyclable with no quality loss

Recycling saves 95% of production energy

Biological Cycle: Wood

Veneer maximizes wood usage vs. solid lumber

FSC-certified options readily available

Natural oil finish—no VOC-heavy varnishes

Decomposable at end of life

Repair at Component Level

Damaged panel or bent Aluminum Extrusion?

Replace one piece, not entire unit

No Planned Obsolescence

No glued assemblies, no proprietary fasteners

Local Production Potential

The system’s simplicity enables distributed manufacturing. Aluminum profiles are globally standardized (20-series extrusions). CNC milling is widely accessible. This means furniture can be produced near end-users, dramatically reducing transportation emissions compared to overseas container shipments. A maker in Berlin, a fabricator in Brooklyn, and a workshop in Shanghai could all produce GRIDWERK pieces from the same digital files.

Digital Innovation: The Web Configurator

Try the interactive proportion viewer !

Bridging Digital Design and Physical Production

The GRIDWERK configurator supports a custom furniture design user experience. As a browser-based 3D interactive proportion viewer, simple CAD-level control

is in users’ hands to test any proportion in real-time. Built with Threejs and WebGL rendering, it provides instant visual feedback as dimensions change.

Current Key Features

Parametric dimension controls (width, height, depth)

Panel Material selection

Camera adjustability for focal length

Real-time 3D preview with material rendering

The Vision

This tool transforms the customer relationship.

Instead of choosing from preset options, users become co-designers. They understand the system, see material implications, and make informed decisions. This is furniture design for the digital age, where the gap between customization and realization shrinks.

Potential Future Functions

- Material quantity calculator

- Export cut list for fabrication

- Estimated cost generator and “Order” button

- Structural validation warnings

- Save and share configurations

- Augmented Reality preview in actual space

- Direct integration with fabricators

- Community gallery of designs

The Making